What is AMFORM?

It’s where the magic happens. Where the U-Haul orange happens. Where raw steel is cut into parts. Of course, these are only a few things that happen at AMFORM.

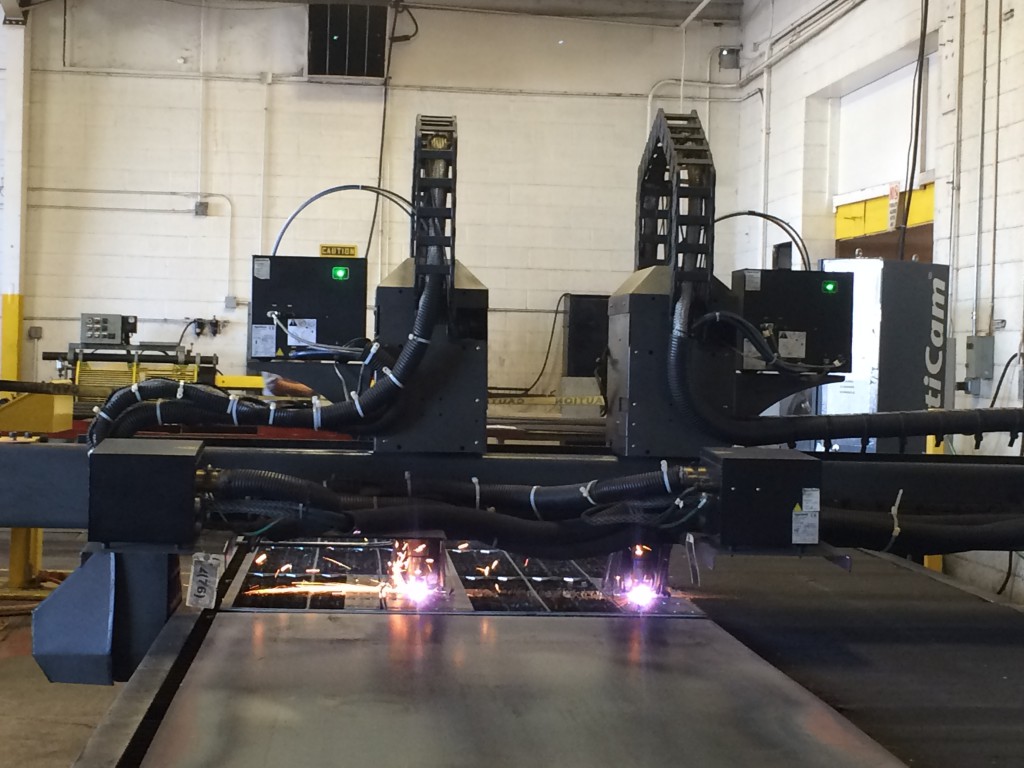

Located in Glendale, AZ, AMFORM, or American Fabricators of Raw Materials, is one of two manufacturing plants for U-Haul products. AMFORM makes all the piece parts for U-Haul products that are then and sent off to assembly plants at either centers in Tempe, AZ or Long Beach, CA. Touring through this manufacturing plant, you’d see expert welders, heavy machinery, lasers, robots, plasma machines and more.

Everything comes to this manufacturing plant in raw form and leaves ready to assemble. New material is cycled out approximately every two weeks. The individuals that work for AMFORM pride themselves in making high-quality parts for our equipment. Here is a notable product that is created at AMFORM:

Utility Dollies

Robotic Technology

Heavy Machinery