U-Haul Team members take the Company’s Primary Service Objective (PSO) seriously: “To provide a better and better product and service to more and more people at a lower and lower cost.”

U-Haul Team members take the Company’s Primary Service Objective (PSO) seriously: “To provide a better and better product and service to more and more people at a lower and lower cost.”

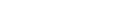

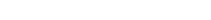

One excellent example of this commitment can be found in the U-Haul Teams at AMFORM, Inc. in Glendale, Ariz., and Falls Manufacturing in Fairless Hills, Pa. By continually looking at better and lower-cost ways to manufacture our products, U-Haul made a commitment to add ABB FlexArc robotic welding cells at both manufacturing plants. These units provide outstanding accuracy and process consistency that world-class manufacturing standards demand.

Robotic arc welding is a high-tech, cost-effective approach to increasing and maximizing throughput in a smaller footprint—doing more with less, which is exactly where “lower and lower cost” comes in.

Each ABB welding cell U-Haul uses has two robotic arms along with a rotating positioner to hold the product being welded. Utilizing the ABB robots enables AMFORM and Falls Manufacturing to produce greater output with fewer resources, resulting in lower overall cost for the products they build to support U-Haul.

Check out the video below to see the robots in action.