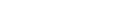

Henry Kelly joined Team U-Haul in 1957. As you can imagine, he has a lot of great stories to tell about his time with U-Haul.

Here, in his own words, he takes a trip down memory lane.

By Henry Kelly

It started when I was an 18-year-old recent graduate of Roman Catholic High School in Philadelphia. The U.S. had a draft system for the Army at that time, and I went to work at a U-Haul location called Willow Grove Manufacturing Company to earn some spending money before going into the military service. I liked the Company from the first day because I was able to use my hands to build and my brain to create.

All my early years were spent stamping parts and building trailers and truck bodies along with repairing all the equipment we would rent. I learned how to press materials, build, assemble, weld, paint, decal, etc. I could do it all start to finish.

When U-Haul acquired Steiner Body in Akron, Ohio, in 1958, four of us volunteered to move from the Willow Grove Plant to Akron and set up a production line to build trailers. Dale Green, a longtime member of Team U-Haul, was on this team, and is still a good friend today.

The men working at this plant took this kid from Philadelphia under their wing and taught me everything about building truck bodies. With their help, I became a craftsman and truck-body builder. This was helpful because the next year, 1959, a kit was sent to Akron to build a body and place it on a Dodge school bus-style chassis, low to the ground for easy loading. I am proud to have been part of the group to have built the first truck used in the U-Haul System.

Eventful first day

I met U-Haul Pioneer Hap Carty working on a trailer design with U-Haul co-founder L.S. Shoen at Willow Grove on my first day. My manager told me that a guy named Eli would be my boss, and that I was only to take instructions from him. L.S. called me over and asked me to get something for him. I informed him only Eli could tell me what to do, and walked away from Hap Carty and L.S. Shoen! I believe they laughed about it, and later in the day I found out who they were. I don’t mind admitting that I was quite embarrassed about what happened that day! Hap and I remain great friends today.

Here’s another L.S. Shoen story. We went to breakfast one morning when I was running the Novi Manufacturing Plant, and L.S. said to the waiter, “I want two four-minute eggs, but do it in two minutes as we are in a hurry to get to our work.” This is something I will never forget!

While I was in Akron, Hap realized that I liked working and didn’t require supervision. I was able and willing to pick up and move around the country, so for the next four years I lived out of a duffel bag and slept on cots in shops across North America, building fixtures and jigs to standardize new production and repair of all U-Haul equipment.

My training in this area came from working with Tom Safford. Notice I said working with, even though I technically worked for him. He did not want to supervise anyone, as he would come and go, often for months at a time.

Tom was an engineering genius, and much of his work is still used in U-Haul today. Working with him was a pleasure. He always wanted to do things rather than explain. His style was to watch and learn, as he felt he could do it faster, and it was up to me to keep up. On one occasion, I had spent a lot of time making a part for him and was very proud of what I had done. He looked at it, said it was good and threw it out the window, as this was not what we were working on at that time.

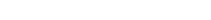

This was all a learning curve to what I would later do for U-Haul. I’ve worked in production, which is all about putting quality in all products. In Human Resources, we’re focused on hiring the right people. And now I’m with Labor Relations, where we make sure they do not take anything away from team members who work hard to serve customers.

After all these years, if you gave me that U-Haul job application, I would fill it out again and not blink an eye. NOW THAT’S PRIDE!