A lot of heavy-duty work goes into assembling U-Haul trucks, trailers and moving supplies at our AMFORM factory. One important piece in the moving process is the coupler–which is a metal part that connects a trailer to its hitch–and here’s a closer look at how this American-made piece of equipment on U-Haul trailers is crafted.

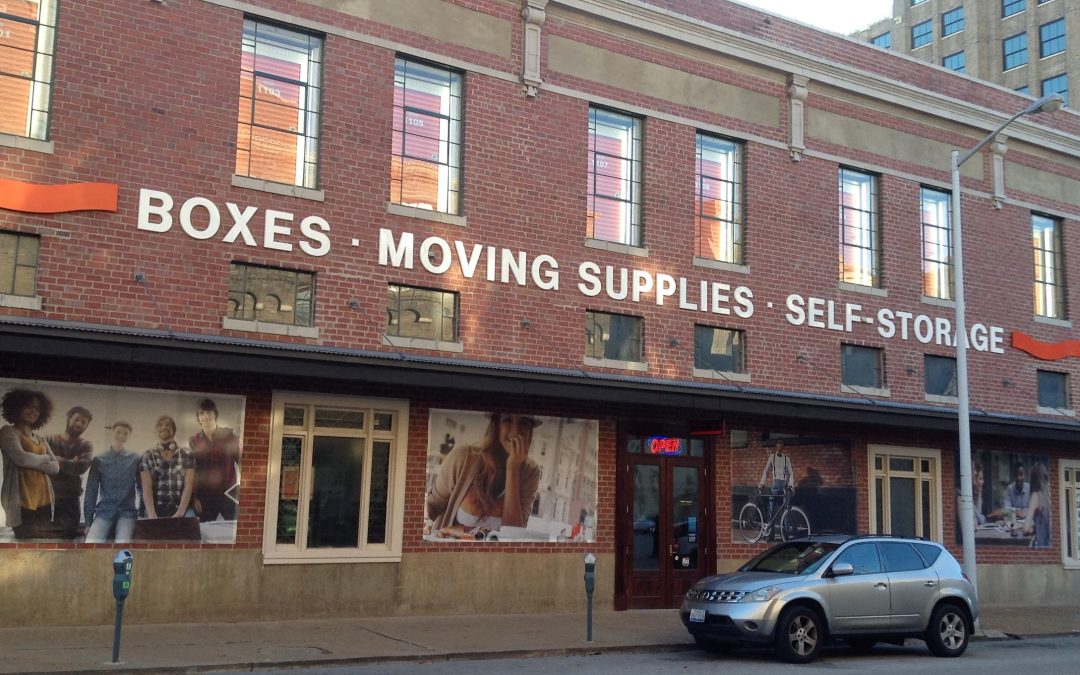

Located in Glendale, Arizona, the AMFORM (American Fabricators of Raw Materials) team creates smaller pieces of U-Haul equipment before shipping them to plants in Tempe or Long Beach to finish the process. Everything enters AMFORM in its raw form and exits ready to assemble for larger equipment–and one of these is the coupler, an important piece in trailer attachment.

Chris Kinney, materials manager at AMFORM, said the team produces more than 30,000 couplers per year, complete with an “original, proven and robust” U-Haul design.

“We’re shipping thousands per month,” Kinney says.

A Whitney machine is used to punch, form and create plasma out of material in smaller parts from anything from bumpers to paneling for products. The skeleton pieces left over are then sold and recycled. It takes 40 tons of pressure to form an anti-slip before the panels are embossed and from steel and aluminum sheets.

The materials for trucks, trailers and dollies are fashioned from domestic-made raw materials, so customers can ensure an all-American process that goes into making their rental items.

A tour of AMFORM takes us over to one U-Haul team member welding a catalytic converter cage/guard out of grade 60 rebar. The metal is galvanized so rust does not form on couplers.

Ramps are then snapped together and welded using aluminum. Next, axles are welded for the bottom of every U-Haul trailer. The couplers aren’t far away from these axles–and all these parts work to ensure safe hitching for trailers.

Each piece is crafted carefully and with maximum precision for our customers everywhere to carry out a successful moving process, every time.

The high-tech ABB robotic welder in the factory can weld anything it’s programmed to, making the coupler creation process impressively efficient! Kinney says the couplers have a “long life and durable galvanizing coating and finish.”

The U-Haul coupler’s “Made in America” status draws customers in to meet their moving needs year after year, with trusty equipment a guarantee!

Do you have a “Made in America” U-Haul story? Let us know in the comments below!