Detroit Thermal, LLC gives new meaning to the term, “blowing off steam” This week the U-Haul Moving and Storage of Detroit got to feel the heat. (Now I’ll never get Robert Palmer out of my head…)

U-Haul is an organization that incorporates sustainable initiatives into our daily business objectives. For us, steam was the obvious choice for heating and Detroit Thermal LLC was also the obvious choice to work with on making steam the renewable energy source to heat our building.

Steam by itself is a great renewable energy source, but not only are we using the steam to heat the building but we are also re-using the water being collected in the condensate line from the steam to provide heat for the radiant flooring.

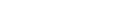

Detroit Thermal LLC has been distributing steam since 1903. Yes, that’s right, over 100 years ago, and back then this concept was considered a modern marvel. The Detroit steam distribution system is one of the oldest and largest in North America. Originally named the Central Heating Company and serving only 12 customers at the time. As the city of Detroit grew, so did the steam system. The primary boiler facility, known as the Beacon Street Plant, commissioned in 1926, is a National Historic Mechanical Engineering Landmark.

In 2010, Detroit Thermal LLC, was acquired by Detroit Renewable Energy LLC, and today provides cost-effective, environmentally friendly heating and cooling services to a group of more than145 buildings along the extended Woodward Corridor from the downtown riverfront to the New Center area using steam produced from renewable energy sources.

In order to make sure we had the right mechanical steam system in place throughout the building we contracted with Detroit Thermal’s preferred mechanical contractor John E. Green, to get this big job done right! There was plenty of work to be completed throughout the seven story building and John E. Green got started on the project immediately and worked diligently on it every day.

With a building as large as this one, one can only imagine the maze of piping it takes to heat the building. Lucky for us, the building was already equipped with a steam system, but it was no easy feat to check this maze of pipes.

Since October 15ththe work on the building began with preparations for the steam system which encompassed weeks of welding, cleaning traps, cleaning the welds, and a lot of intensive, hard work. Then we needed to ensure that any pipes needing to be rerouted were only rerouted if absolutely necessary. A new steam service line was also installed.

Let the testing begin….with seven floors to test, we needed to turn up the heat slowly in order to observe the welding and to be certain everything was operating correctly. So floor to floor we go….this is a long process, since as the steam is flowing through pipes and condensate lines, the condensate lines have built up minerals that flake off and fill up the traps initially, so slow is the only way to go to ensure a hot and steamy delivery. As of today, we are 80 percent complete with testing and our showroom is toasty warm!

Thanks to Detroit Thermal and John E. Green on the job – we couldn’t have been more happy with the work and the outcome of what was accomplished in such a short time frame – thank you for helping make our project become a reality!

Do you have steam? Let us know what you think of steam as a renewable energy source.

– Joeygirl